- Home

- Blogs

Data Analytics In Manufacturing Industry: Unlocking Efficiency And Growth

The manufacturing industry has undergone significant transformations in recent years, driven by advancements in technology and the increasing need for efficiency and competitiveness. One key area that has emerged as a crucial component of this transformation is data analytics in manufacturing industry. By leveraging data analytics, manufacturers can gain valuable insights into their operations, optimize processes, and make data-driven decisions to drive growth and profitability.

What is Data Analytics in Manufacturing?

Data analytics in manufacturing industry involves the use of statistical methods and analytical techniques to extract insights from large datasets generated by various sources within the manufacturing process. This includes data from sensors, machines, and other equipment, as well as data from supply chain management, inventory control, and customer interactions. By analyzing this data, manufacturers can identify trends, patterns, and correlations that can inform strategic decisions and improve operational efficiency.

Types Of Manufacturing Data Analytics

Data analytics in manufacturing industry encompasses various types, including:

Descriptive Analytics

Descriptive analytics involves analyzing historical data to understand past performance and trends. Manufacturers use descriptive analytics to monitor key performance indicators (KPIs), track production metrics, and identify areas for improvement.

Predictive Analytics

Predictive analytics uses statistical algorithms and machine learning techniques to forecast future outcomes and trends. Manufacturers use predictive analytics to predict equipment failures, forecast demand, optimize production schedules, and anticipate market trends.

Prescriptive Analytics

Prescriptive analytics recommends optimal courses of action based on predictive insights to improve decision-making. Manufacturers use prescriptive analytics to identify the best course of action to achieve specific goals or objectives, such as optimizing production schedules, minimizing costs, or maximizing profits.

Diagnostic Analytics

Diagnostic analytics involves identifying the root causes of problems or failures by analyzing historical data. Manufacturers use diagnostic analytics to investigate production issues, identify inefficiencies, and implement corrective actions to improve performance.

Application of Predictive Analytics in Manufacturing Industry.

Predictive Analytics is the use of historical data, algorithms, patterns, big data, artificial intelligence, and machine learning techniques to predict the future outcomes of a current problem. The insights will help you make informed decisions about the future odds, lessen unplanned downtime, improve operations, mitigate risks, eradicate unnecessary maintenance costs, predict vital outcomes, and increase revenue. The predictive analytics models are idolized as a panacea to a lot of manufacturing problems.

Manufacturing Industry

Planning and efficiency are the main focus of the manufacturing business. Predictive analytics models are used in manufacturing through machines that have data sensors and connected devices. It enables the data scientists to gather and monitor data from these machines, identify the source of problems, and understand where maintenance is required. By predicting these problems, businesses can save huge money and time. The data analytics models can be leveraged to improve the quality of the machines, predict the demand and supply, and schedule machine usage for maximum utilization. With the use of big data and machine learning techniques, businesses can stay organized, increase their efficiency and services.

Benefits of machine learning predictive analytics in the manufacturing industry

Foresee machine failures

One of the most prominent benefits of PA is the ability to continuously monitor machines and use historical data to foresee future machine failures. It is done by the sensors placed inside the machines to monitor the operational framework and machine conditions. The data will be sent from the sensor to other devices. This data will help manufacturers assess the machine’s performance in real time and predict the odds.

Stop workplace injuries

Besides protecting the machine’s health, big data predictive analytics can prevent workplace injuries. The workplace usually demands proactive health strategies, and PA can indicate such future hazards thereby, reducing injuries and mortality rates.

Lessen operational costs

Failures directly translate into serious product losses, labor productivity, time, and overhead. The business intelligence predictive analytics method will enable manufacturers to discover failures and take reparative measures to minimize impact and lessen the associated costs. In addition, it will also lessen the unplanned downtime and wasted productivity.

Optimize for betterment

Practices like ‘Lean Principles’ help manufacturers pull off extreme production efficiency with minimal waste. PA supplies manufacturers with real data to help them optimize their business processes for the betterment and to attain perfection. It enables manufacturing industries and other organizations to operate more efficiently.

Optimize supply chain

With predictive analytics, you can apprehend demand signals that connote marketplace changes. It will help you position your supply chain to demand oscillations faster. Reduce inventory costs and waste while increasing your CSAT scores.

Applications of Manufacturing Data Analytics

Predictive Maintenance:

One of the most compelling applications of manufacturing data analytics is predictive maintenance. By leveraging historical data and real-time sensor readings, manufacturers can anticipate equipment failures before they occur, thereby minimizing downtime and reducing maintenance costs. Predictive maintenance strategies not only enhance operational efficiency but also extend the lifespan of critical machinery.

Quality Control:

Ensuring product quality is paramount in the manufacturing industry. Data analytics enables manufacturers to implement sophisticated quality control measures by analyzing production data to detect anomalies and deviations from predefined standards. By identifying quality issues early in the production process, manufacturers can mitigate defects and enhance customer satisfaction.

Supply Chain Optimization:

The modern manufacturing landscape is characterized by complex supply chains spanning multiple geographies and stakeholders. Data analytics provides manufacturers with valuable insights into supply chain dynamics, enabling them to optimize inventory management, streamline logistics, and mitigate supply chain risks. By leveraging big data analytics, manufacturers can achieve greater visibility and agility across their supply networks.

Process Optimization:

Continuous improvement is essential for maintaining competitiveness in the manufacturing industry. Data analytics empowers manufacturers to optimize production processes by identifying inefficiencies, bottlenecks, and areas for improvement. Through real-time monitoring and analysis, manufacturers can fine-tune their operations to enhance productivity, reduce waste, and optimize resource utilization.

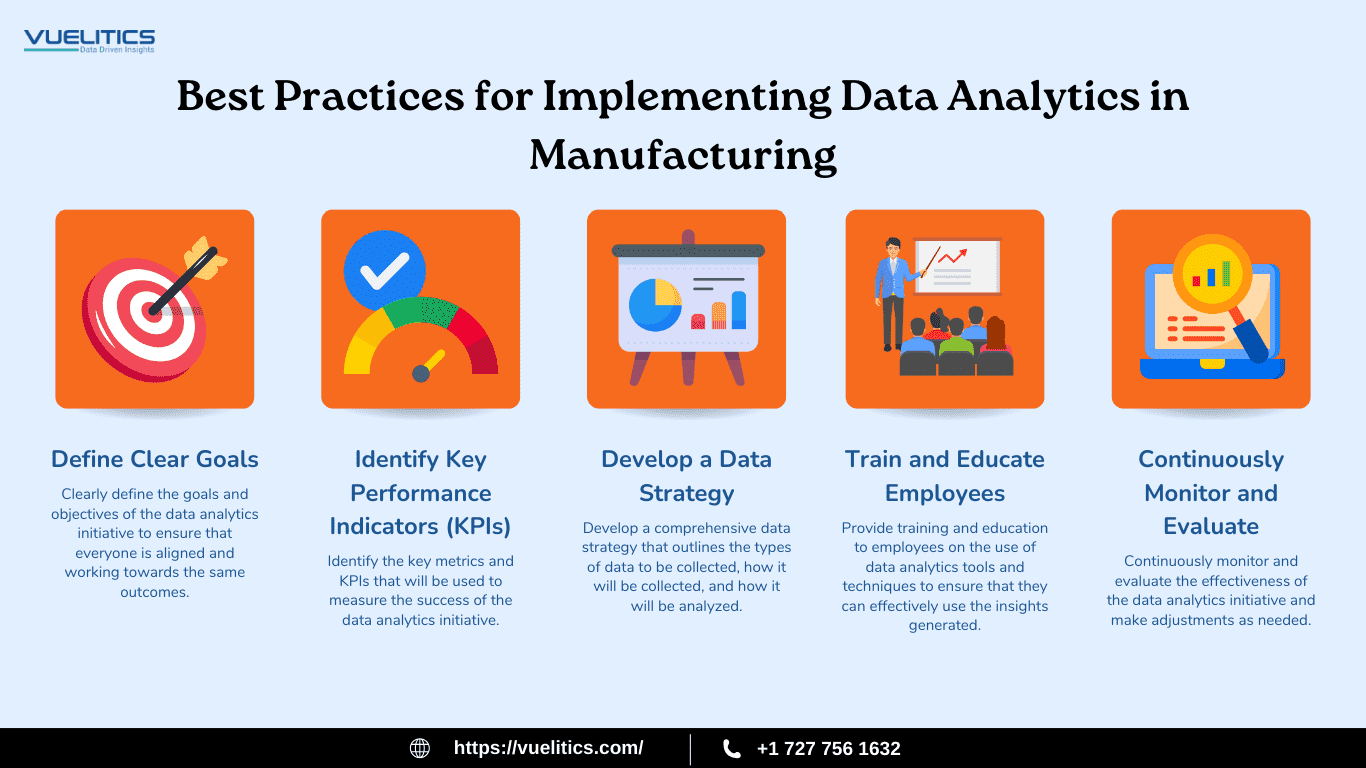

Best Practices for Implementing Manufacturing Data Analytics

Implementing manufacturing analytics requires careful planning and execution. Some best practices include:

Define Clear Goals:

- Clearly define the goals and objectives of the data analytics initiative to ensure that everyone is aligned and working towards the same outcomes.

Identify Key Performance Indicators (KPIs):

- Identify the key metrics and KPIs that will be used to measure the success of the data analytics initiative.

Develop a Data Strategy:

- Develop a comprehensive data strategy that outlines the types of data to be collected, how it will be collected, and how it will be analyzed.

Train and Educate Employees:

- Provide training and education to employees on the use of data analytics tools and techniques to ensure that they can effectively use the insights generated.

Continuously Monitor and Evaluate:

- Continuously monitor and evaluate the effectiveness of the data analytics initiative and make adjustments as needed.

Technologies and Tools for Data Analytics in Manufacturing Industry

The manufacturing industry is increasingly leveraging various technologies and tools for data analytics to optimize processes, improve quality, and drive efficiency. Here are some of the key technologies and tools being used:

Big Data and Analytics Platforms

- Apache Spark: An open-source data processing engine that supports large-scale data processing and analytics.

- Hadoop: A framework that allows for the distributed processing of large datasets across clusters of computers.

- Snowflake: A cloud-based data warehouse that provides scalable storage and computing power for data analytics.

Industrial IoT (IIoT) and Edge Computing

- IIoT sensors: Sensors embedded in manufacturing equipment that collect real-time data on performance, maintenance needs, and quality.

- Edge computing: Processing data at the edge, close to where it is generated, to enable faster insights and decision-making.

Predictive and Prescriptive Analytics

- Machine learning algorithms: Used to analyze historical data and predict future outcomes, such as equipment failures or quality issues.

- Prescriptive analytics: Uses optimization and simulation models to recommend the best course of action based on predicted outcomes.

Data Visualization and Reporting Tools

- Tableau: A popular data visualization platform that allows users to create interactive dashboards and reports.

- Power BI: Microsoft’s business intelligence platform that provides data visualization, reporting, and analytics capabilities.

- Spotfire: A data visualization and analytics platform designed for manufacturing use cases.

Manufacturing-Specific Analytics Software

- MachineMetrics: Provides real-time production monitoring, predictive maintenance, and supply chain optimization for manufacturers.

- Datapine: A business intelligence platform with features tailored for manufacturing analytics, such as production volume tracking and downtime analysis.

These technologies and tools, when combined with domain expertise and a focus on data management, enable manufacturers to unlock the full potential of data analytics to drive operational excellence and competitive advantage.

Challenges and Future Trends of Data Analytics in the Manufacturing Industry

The manufacturing industry faces several challenges and trends that will shape its future. Here are some key points:

Challenges of Data Analytics in the Manufacturing Industry:

Supply Chain Disruptions:

- Supply chain management issues continue to impact 37.8% of manufacturing companies, with raw material costs being the number one supply chain threat.

Labor Shortages:

- Manufacturers are facing a tight labor market and high turnover rates, with an estimated 2.1 million manufacturing jobs going unfilled by 2030.

Cybersecurity:

- With the increasing use of Industrial Internet of Things (IIoT) technologies, cybersecurity risks are becoming more critical, and maintaining multiple layers of security is essential.

Carbon Neutrality:

- Manufacturers are under pressure to reduce their carbon footprint, with one-fifth of the world’s carbon emissions coming from the manufacturing and production sectors.

Future Trends in Data Analytics in the Manufacturing Industry:

Role-Based Upskilling Programs:

- Manufacturers are adopting role-based training and upskilling programs to address the skills gap and attract and retain the next generation of talent.

AI and Generative AI (Gen AI):

- AI and gen AI will continue to play a crucial role in smarter operations, improving efficiency and productivity across multiple sectors.

Digital Maturity:

- Manufacturers must increase digital maturity by investing in IoT devices, AI and machine learning, and automation to gain a competitive edge.

Sustainability:

- Sustainability is becoming a key focus, with manufacturers prioritizing eco-friendly initiatives and greener processes to meet ESG goals and customer demands.

Predictive Maintenance:

- Predictive maintenance will become more prevalent, using data analytics and AI to predict equipment failures and reduce downtime.

Smart Factories:

- Smart factories will continue to emerge, leveraging advanced data analytics technologies to optimize operations and improve efficiency.

Reshoring:

- Reshoring will become more prominent, as manufacturers seek to build resilience and mitigate supply chain risks by bringing production back to their home countries.

Predictive Analytics:

- Predictive analytics will be used to forecast demand, optimize production, and improve supply chain management.

These trends and challenges highlight the need for manufacturers to adapt to changing global dynamics, invest in digital technologies, and prioritize sustainability to ensure their future success.

A Case Study of Manufacturing Data Analytics

Synopsis

The challenge was to establish a trend of products in demand, yet out-of-stock in retail outlets, in order to establish proactive manufacturing.

Solution

Vuelitics worked on bringing in 5 years of historical data into the client’s QlikView setup and extracting visually insightful trends to address the client’s business question.

To learn more about this case study and how Vuelitics helped the client achieve proactive manufacturing, please download the full case study from the link provided:

Download a case study of data analytics in manufacturing industry.

Conclusion

In conclusion, data analytics is revolutionizing manufacturing, offering unprecedented opportunities for efficiency and innovation. At Vuelitics, we specialize in business intelligence and data analytics consulting services, empowering manufacturers to optimize operations and drive sustainable growth. Join us in embracing the power of data analytics to unlock new levels of competitiveness and success in the digital age of manufacturing.

Post Comments